A glimpse at the many stages of our manufacturing process, which combines traditional techniques and modern technology.

Computer aided technology

Laser cutting machines, CNC milling machines, laser engraving machines are now an integral part of our production line, making Topkapi a one step complete service provider.

Cutting of metal sheets

The main raw material for silverware consists of large brass sheets which are cut and then sent for forming, welding and polishing.

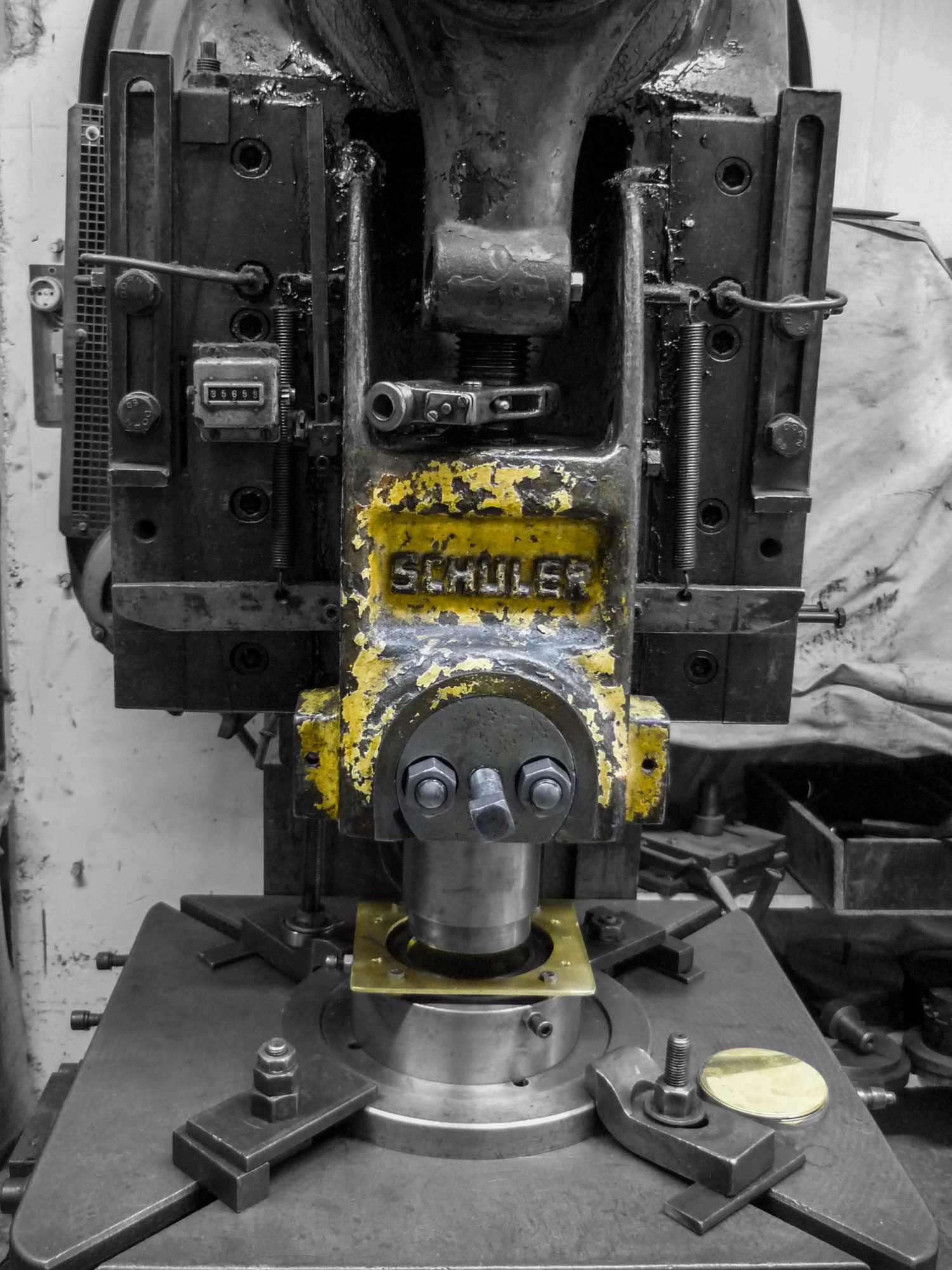

Pressing

Hydraulic and eccentric presses are used to create all sorts of shapes based on our growing collection of molds.

Metal spinning

Metal spinning, also known as spin forming or spinning or metal turning most commonly, is a metalworking process by which a disc or tube of metal is rotated at high speed and formed into an axially symmetric part.

Annealing the metal

Spinning and pressing deep brass items often requires heating, to soften the metal.

Sand casting

Sand casting,is a metal casting process characterized by using sand as the mold material is a beautiful traditional technique for duplicating brass and aluminum items.

Precision welding

Welding brass is a very delicate operation that requires a lot of experience to insure perfect finishing.

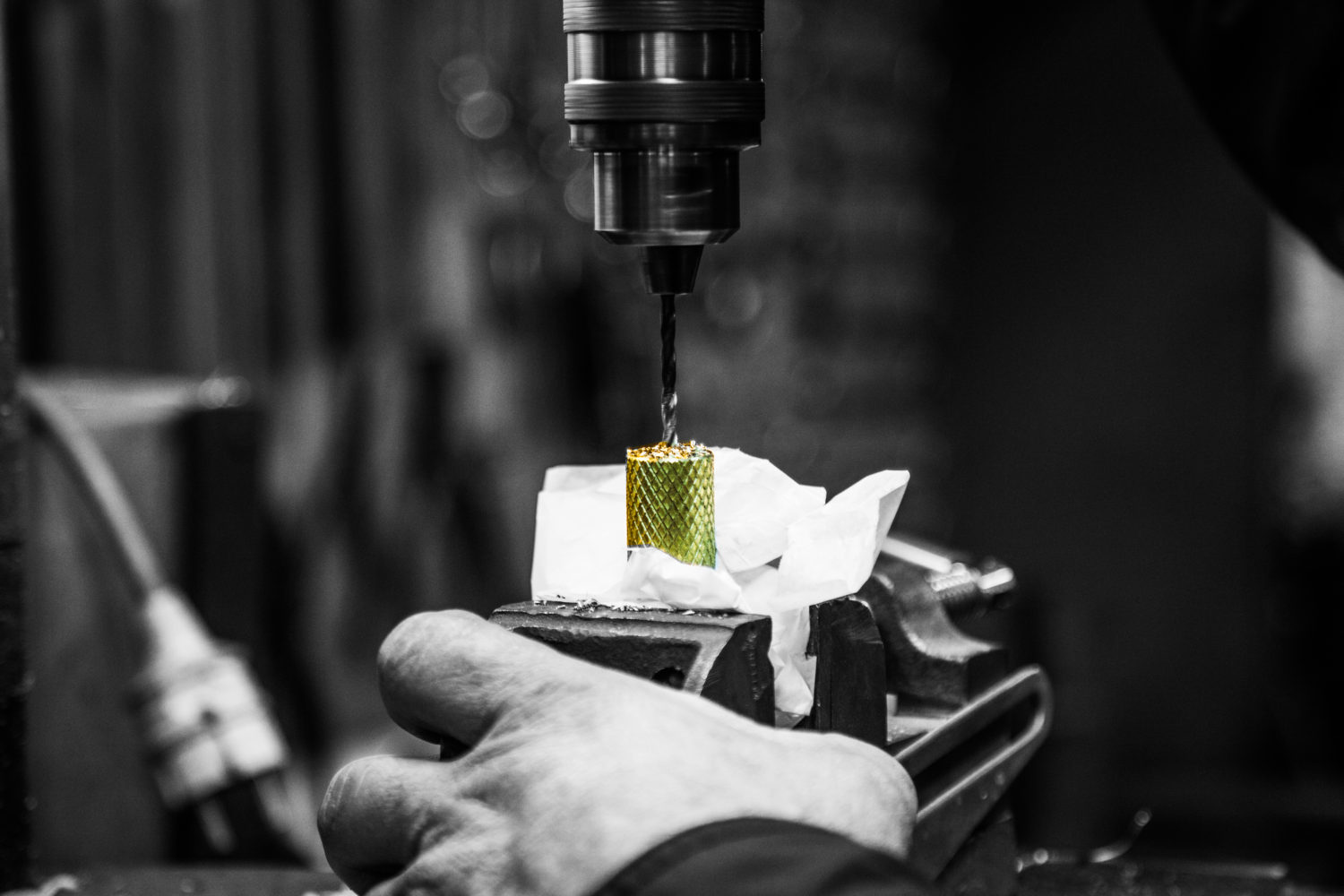

Precision work

All steps, require input from skilled technicians that spent years mastering their craft.

Traditional milling

Mills are used to cut precision parts and all kinds of molds for spinning.

High quality plating

One of the secrets to manufacturing high quality durable silverware resides in those plating baths. Electroplating techniques are used to achieve nickel, silver and gold coating of brass items.

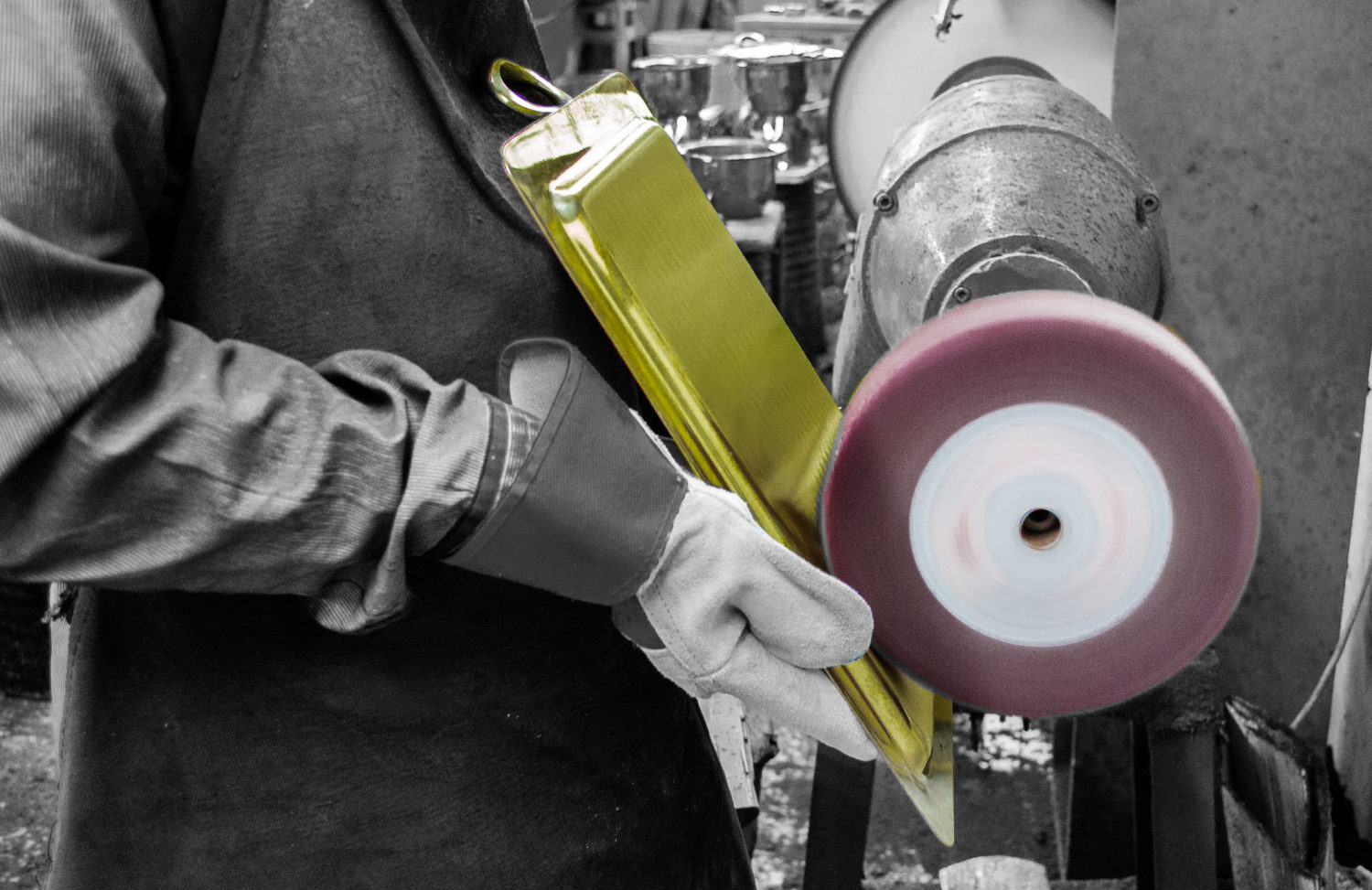

Polishing

Polishing is an essential part of silverware making and is required at several stages of the manufacturing process.